Foundation and Support Structures

The Research Centre for Steel, Timber and Masonry of the Karlsruhe Institute of Technology (VAKA) possesses a far reaching knowledge considering design and optimisation of foundation and support structures for off- and onshore wind energy plants.

Using FE-Software like ANSYS and ABAQUS as well as the high performance computers of the Steinbuch Centre for Computing at KIT, detailed numerical analyses (static and dynamic) can be performed. Utilizing the hardware and software available at KIT fatigue analysis of complex structures can be realised.

The foundations for onshore wind turbines are most often made of reinforced concrete. The connection between the supporting structure and the foundation is realized with the help of ring-formed mounting parts made of steel or pre-stressed foundation baskets. In this foundation area, the entire construction needs to be particularly well designed for high cycle fatigue stress with a cycle-to-failure of up to N = 109.

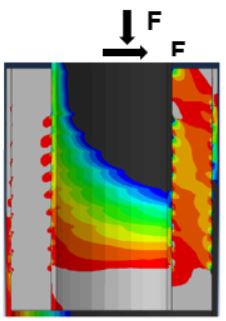

Offshore, knowledge about the supporting and fatigue stress behavior in the connecting elements between the base and the tower (transition pieces) is vital to the availability and life expectancy management.

- welds,

- flange connections,

- grout connections